ZF1 PAYLOAD

Blower system

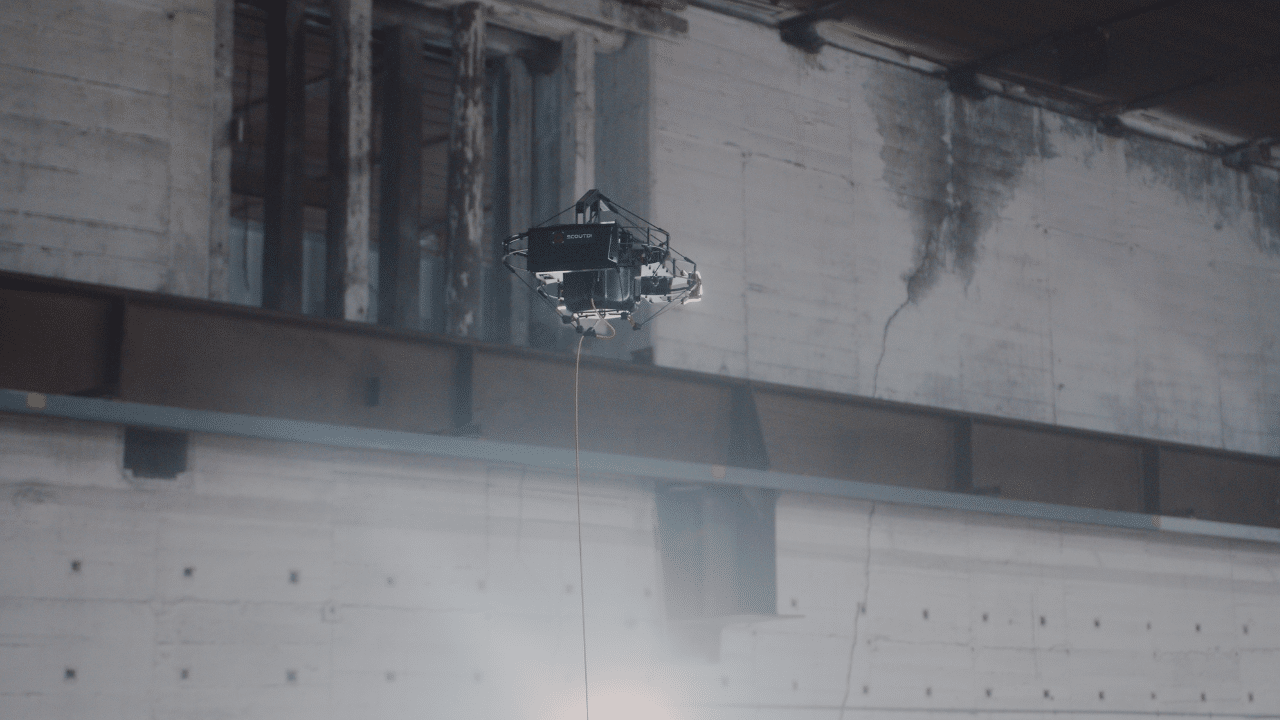

In collaboration with Scout DI, Zeeef has developed an innovative air blowing system for the Scout DI 137 drone. The ZF1 payload, capable of removing all types of dust with a speed exceeding 100 km/h, is patented and has proven its effectiveness for over 8 years.

UNLIMITED

flight time

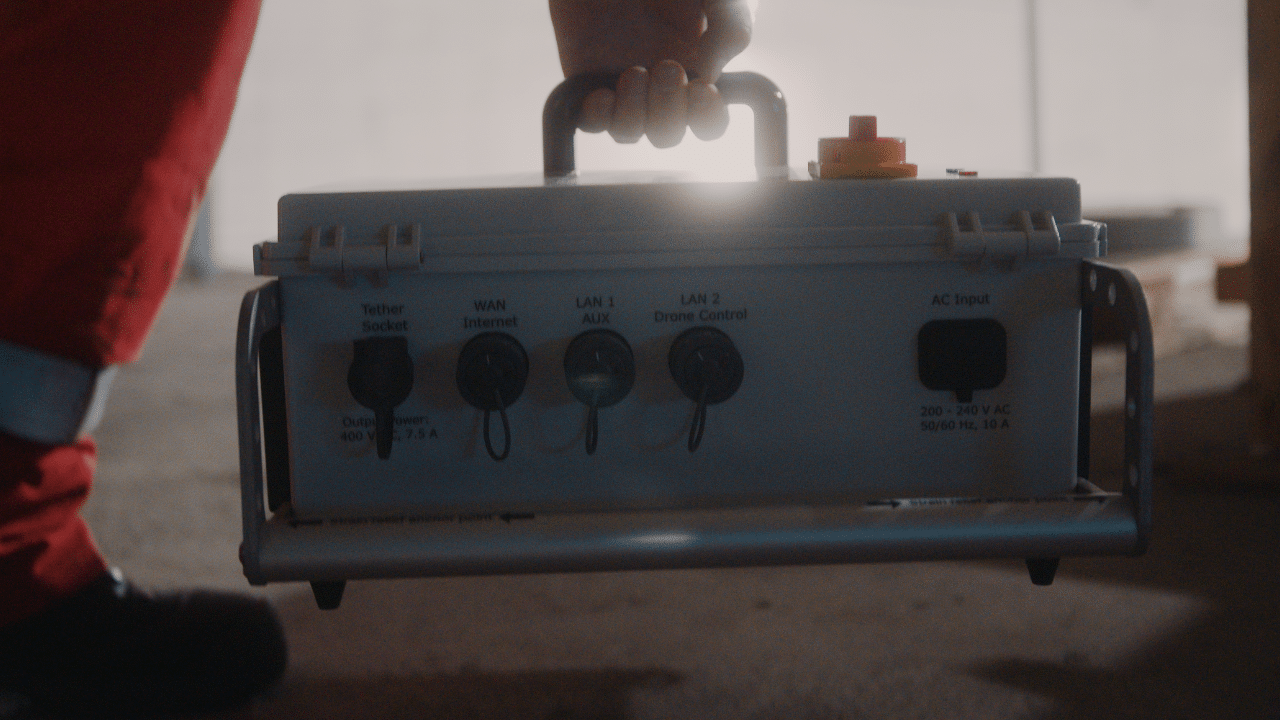

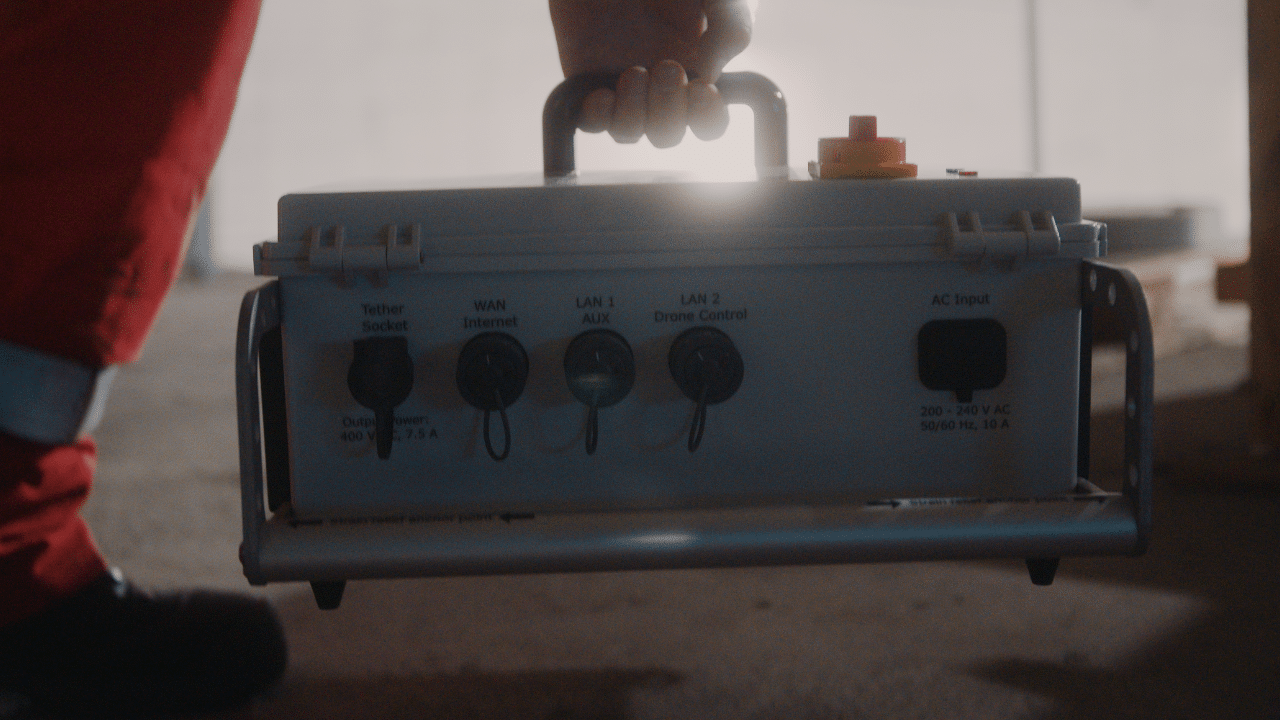

The Scout DI 137 drone is connected to a ground station and operates without a battery. This allows for unlimited flight time and a reliable, fully wired control path. With no need for battery changes, external distractions are eliminated and response times are significantly reduced.

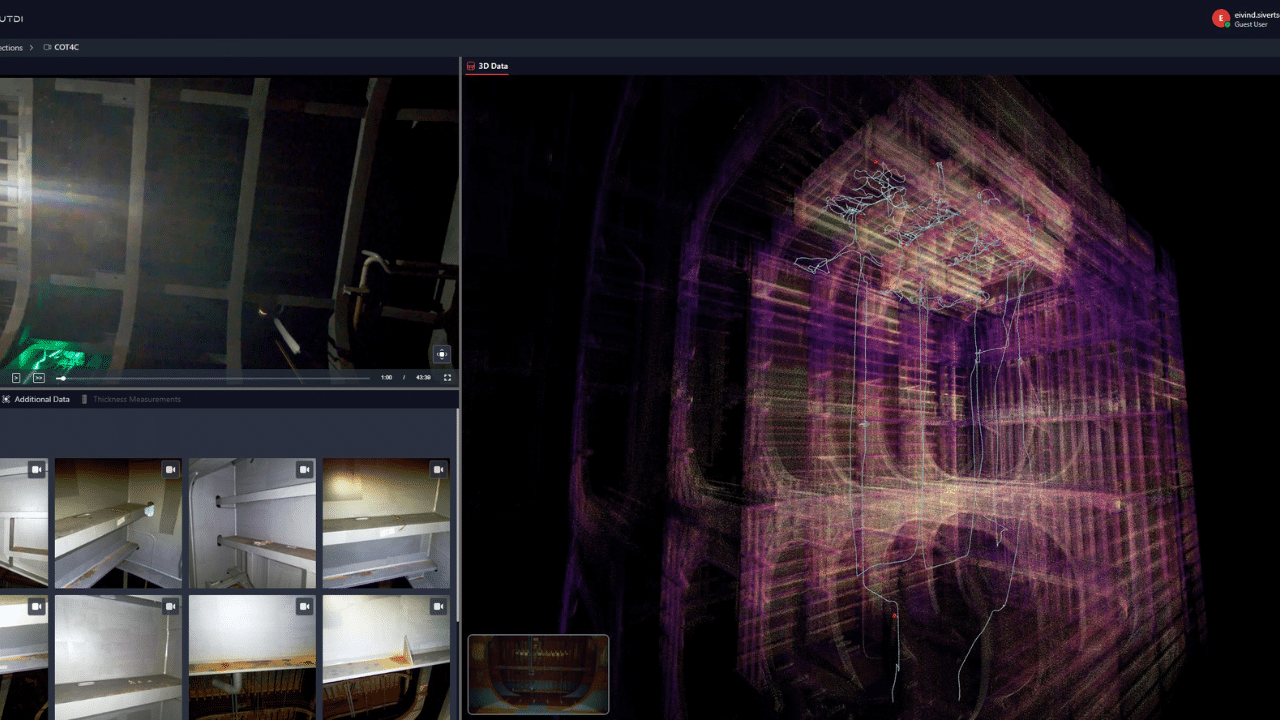

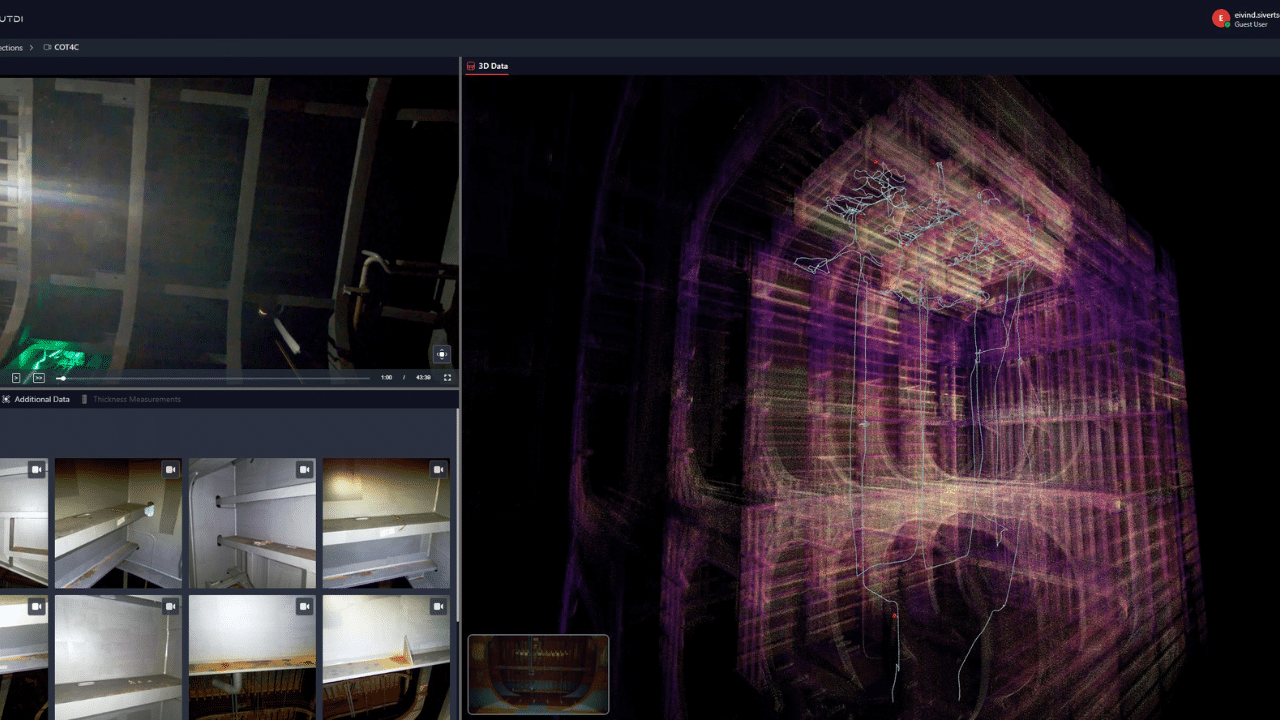

REAL-TIME VIEW

and monitoring of operations.

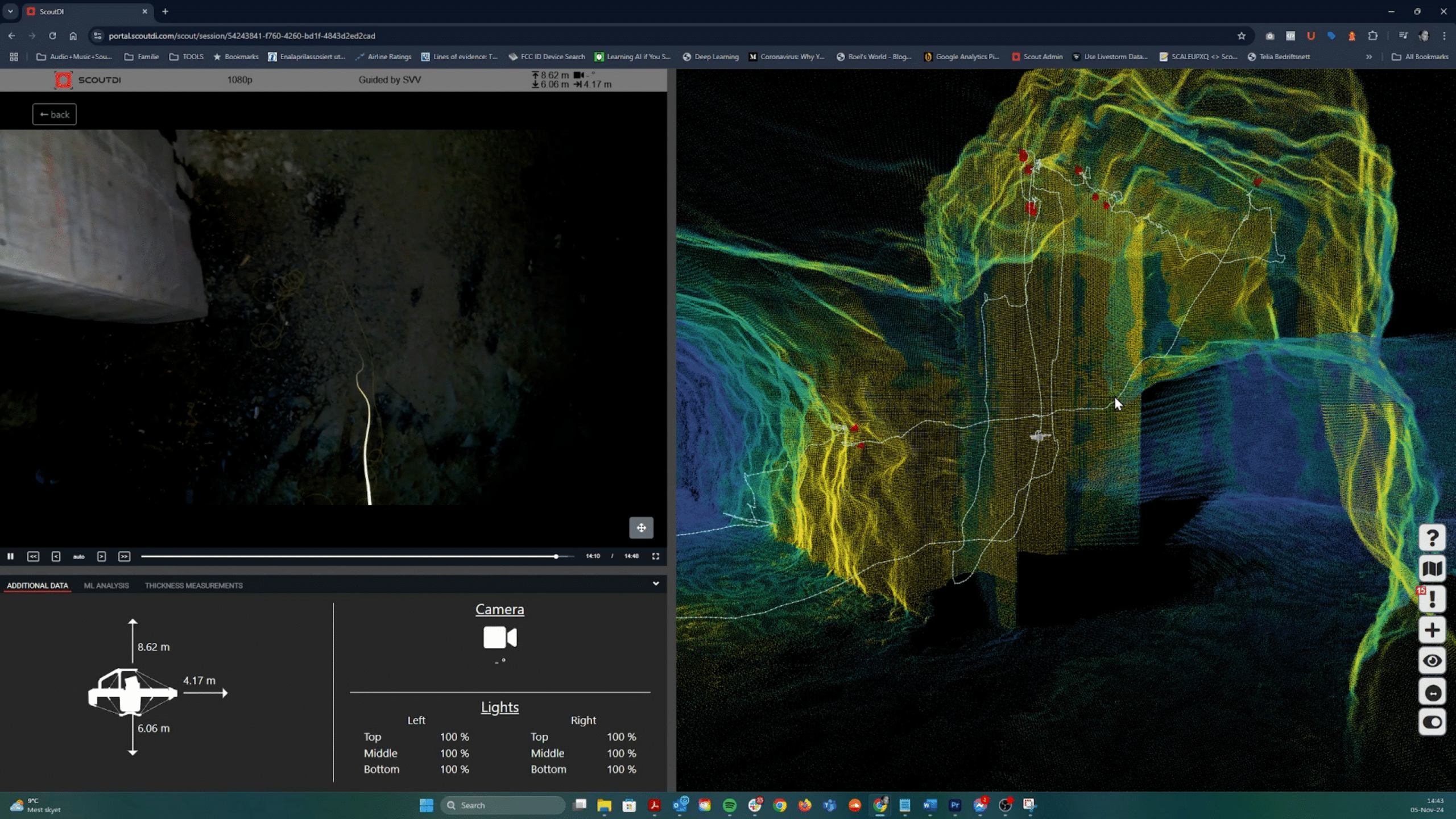

The Scout DI 137 application allows full control of the drone system’s functions and provides real-time display of the camera feed, LiDAR point cloud, and the mini-map.

DATA ANALYSIS

via Scout Portal

Scout Portal is a powerful cloud-based platform designed to analyze, report, store, and back up data from services performed in industrial environments. Using SLAM technology, it generates a 3D point cloud of the site, displaying all visual points of interest. This approach enhances dusting operations by providing accurate and documented inspections, adding significant value in terms of control and tracking.

EXTRA PAYLOADS

for additional services.

The Scout DI 137 drone is equipped with a ZF1 air blowing payload, a 3D LiDAR sensor, and a high-resolution fixed lens camera. But that’s not all: to complement dusting operations, additional payloads can be added, such as a gas sensor and an ultrasonic thickness measurement tool.

SCOUT DI 137

drone system

Scout Portal

Online data analysis platform

FAQS

your questions, answered

What is an industrial dusting drone?

The industrial dusting drone is a remote-controlled device designed to clean and remove dust, particles, and debris accumulated in hard-to-reach industrial environments.

How does the industrial dust removal drone work?

The industrial dust removal drone offered by Zeeef has been developed based on the Scout DI 137 drone, incorporating a payload called ZF1, which allows it to blow and eliminate all types of dust.

Which industries can benefit from this technology?

How efficient is the ZF1 payload compared to traditional cleaning methods?

The ZF1 payload offers several advantages over conventional cleaning methods:

-

Enhanced safety by reducing worker exposure to hazardous environments.

-

Significant time savings, eliminating the need for scaffolding or cranes.

-

Reduced maintenance costs through effective cleaning.

-

Lower insurance premiums due to improved safety standards.

What is the cleaning capacity of the ZF1 payload?

What types of dust and debris can it remove?

The ZF1 Payload is capable of handling various types of industrial dust and debris, including:

-

Fine and Suspended Particles: Cement, wood, metal, and textile dust.

-

Soot and Combustion Residues: Soot from thermal power plants, carbon deposits, and fly ash.

-

Organic and Food-Related Dust: Cereal, flour, sugar, and cocoa dust.

-

Industrial Debris and Contaminants: Wood shavings, plastic residues, dry paint, glass, and ceramic particles.

Is the drone safe for indoor use?

Yes, the Scout DI 137 Drone is equipped with advanced navigation and obstacle avoidance technologies, making it safe for indoor operations. It is also undergoing certification to meet ATEX standards for use in explosive environments, such as grain silos and chemical plants.

How is the Scout DI 137 drone operated?

The Scout DI 137 drone is piloted using a standard drone remote control. Zeeef’s operators are trained in indoor piloting and are proficient in utilizing all of the drone’s features.