Introduction

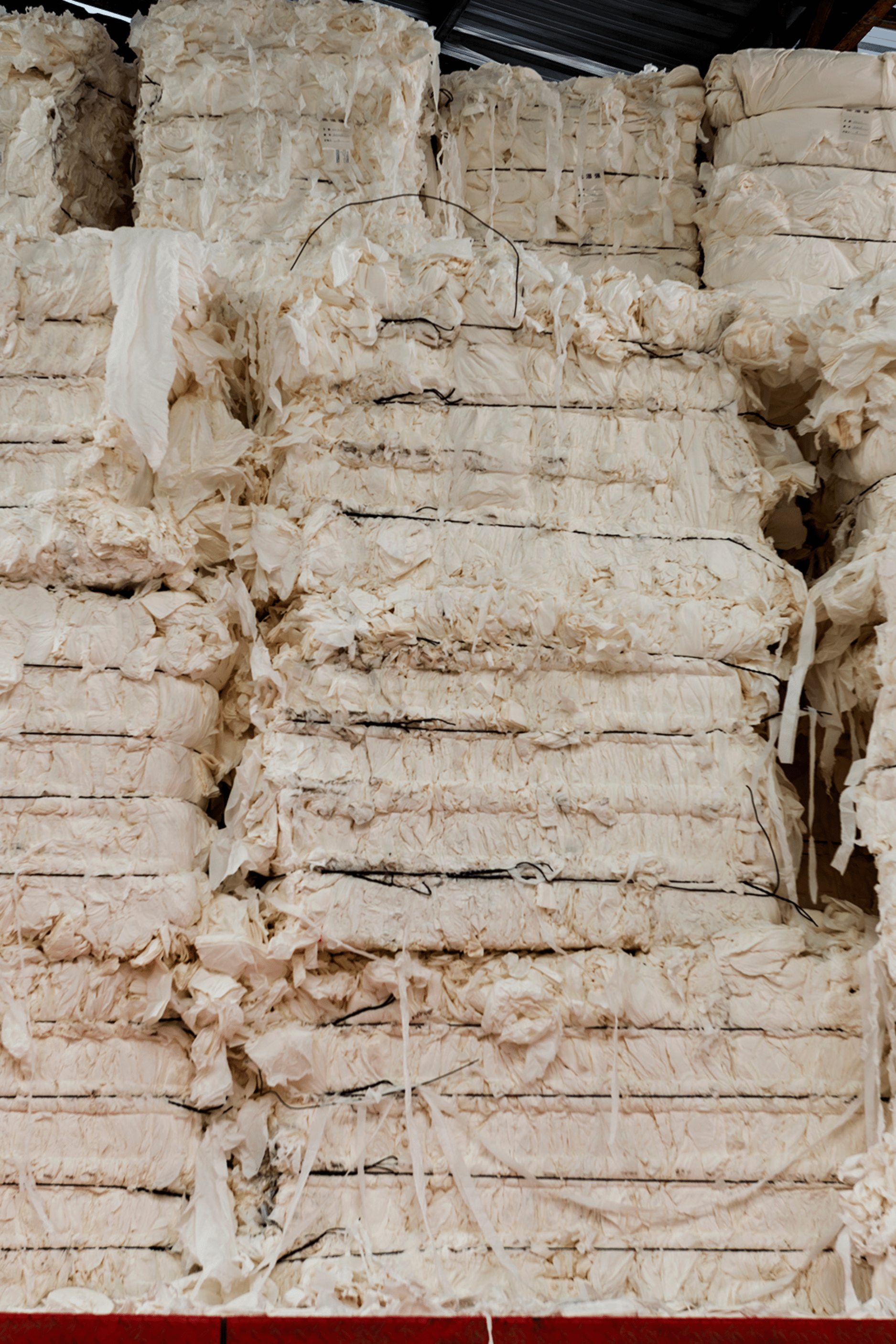

In the paper industry, particularly in manufacturing, processing, and printing plants, production generates a significant amount of dust, fibers, and airborne particles. These residues gradually accumulate on beams, ventilation ducts, light fixtures, and production machines.

+15CM

of dust accumulated each year

10 DAYS

of annual cleaning-related downtime.

+5000

industrial fires reported each year

Dust Accumulation

A Hidden Threat in Paper Industry

1. Decreased Production Output

Air pollution and the accumulation of residues in paper mills directly affect the quality of the products being manufactured. Due to the presence of airborne particles such as fibers, dust, and other impurities, the paper sheets in production are at risk of contamination throughout the process.

When these particles settle on the paper sheets or rolls, they can alter their appearance, texture, and cleanliness.

This contamination can lead to visible defects, such as stains, irregularities in the paper, or color variations, which harm the consistency and final quality of the product. For certain types of paper, such as those intended for high-quality printing or specific applications, these alterations can render the products non-compliant with customer requirements and industry quality standards.

2. Air Quality Deterioration

The excessive presence of dust in the ambient air presents a significant health issue in paper production plants. These fine particles, which result from the processing of pulp, grinding, and fiber transformation, remain suspended in the air and can be inhaled daily by employees, increasing health risks.

Prolonged exposure to these residues can lead to various respiratory problems, such as asthma, chronic bronchitis, or lung infections, especially among the most sensitive workers. The dust generated during the paper manufacturing process can also cause skin irritation and allergic reactions, leading to redness, itching, or inflammation of the respiratory passages.

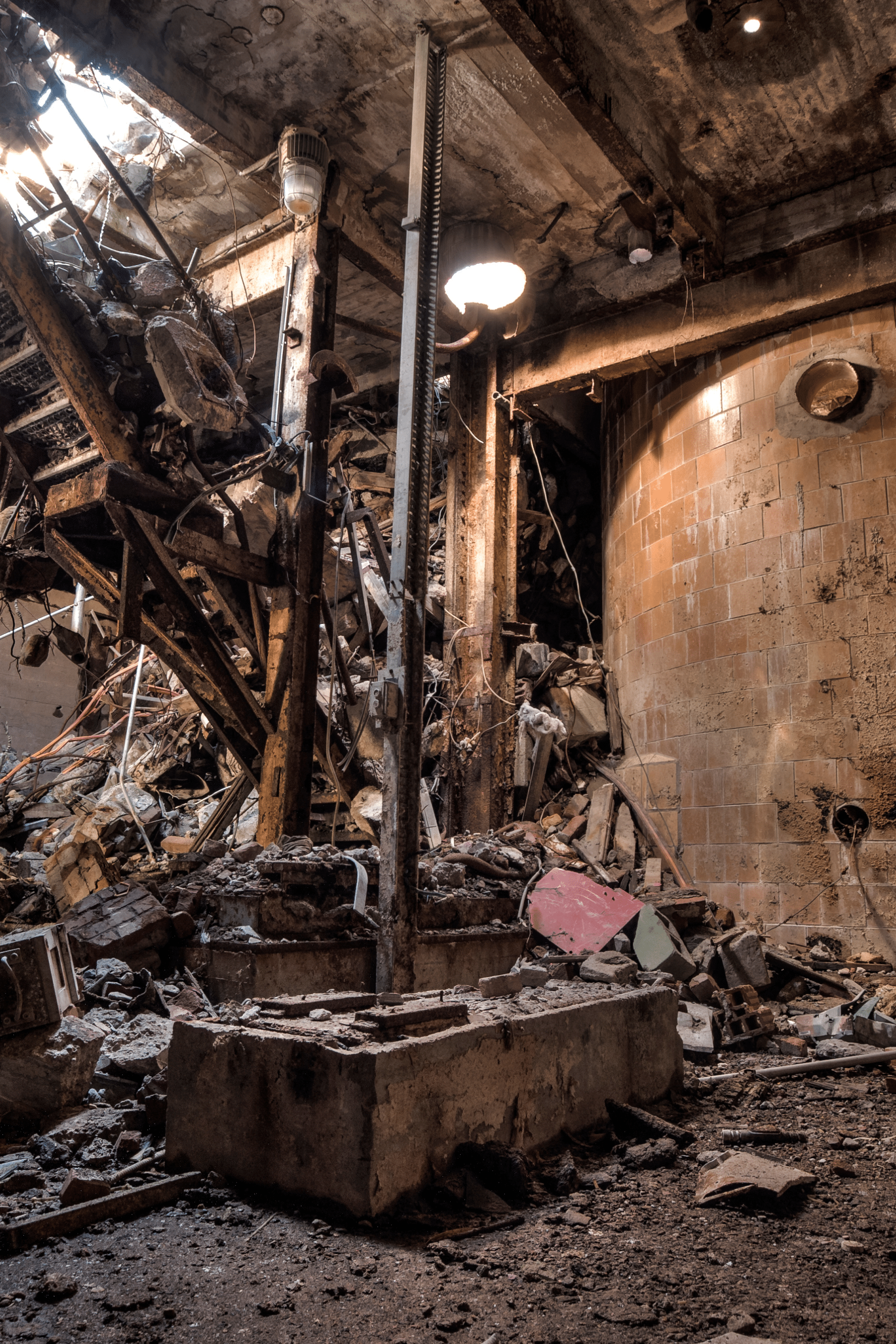

3.Elevated Risk of Fire and Explosion

A gradual buildup of dust and paper fibers poses several critical risks to the safety of your facilities. In particular, the high concentration of particles in the air becomes a major fire hazard. Paper fibers, whether from pulp or wood, are highly flammable and can easily ignite when exposed to heat, a spark, or even simple friction. This can lead to rapid and uncontrolled combustion, spreading the fire throughout production areas and significantly increasing the danger to your employees and equipment.

This risk is even higher in environments where ventilation or air conditioning systems may redistribute these flammable particles in the air, further increasing the likelihood of a fire starting. Therefore, it’s essential to maintain a clean and safe working environment by implementing effective preventive measures to limit the accumulation of dust.

4. Increased Operational Maintenance Costs

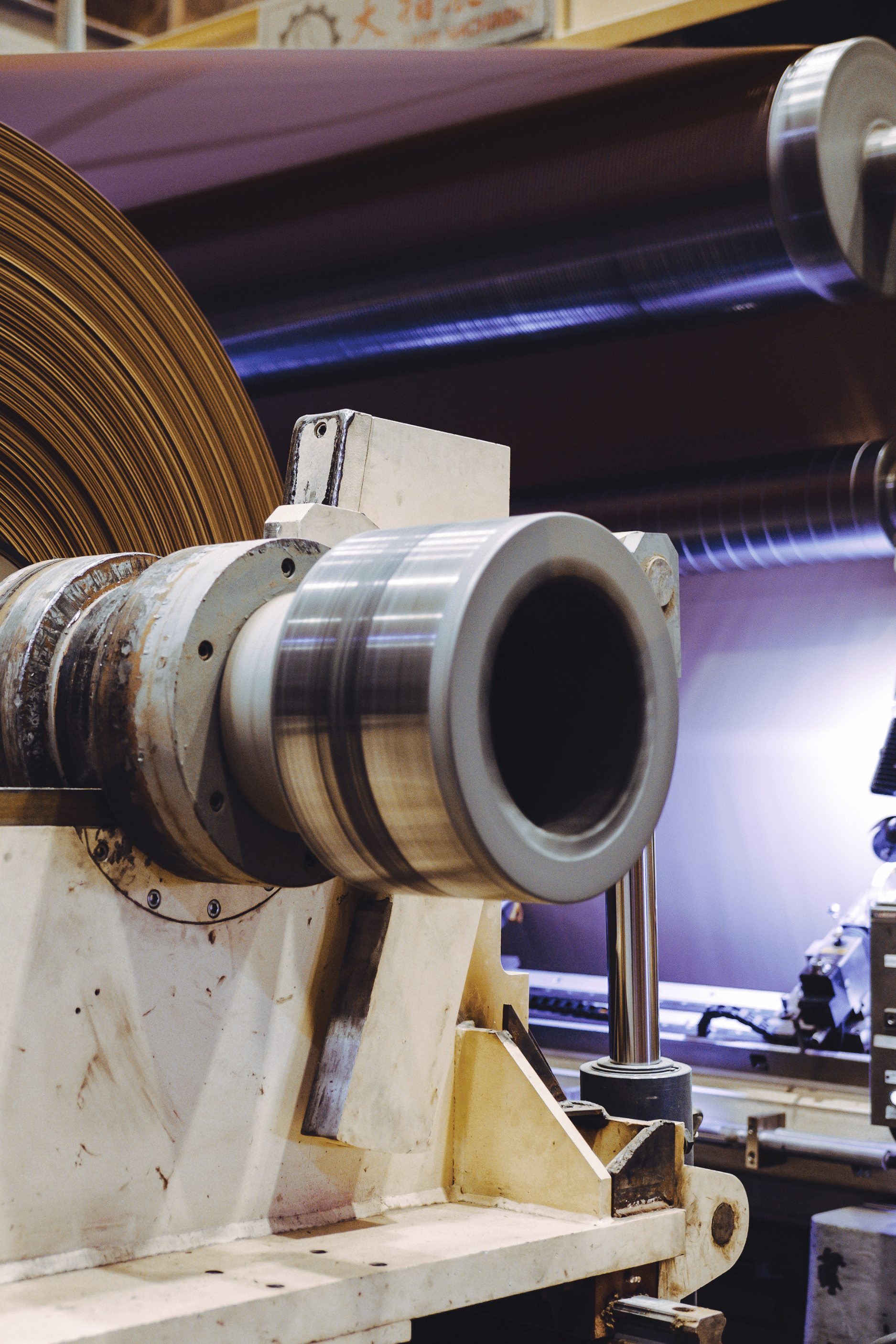

The buildup of dust and paper fibers on equipment can have serious consequences for the operation of machines in a paper production plant. When these residues accumulate on machine components (such as rollers, motors, filters, belts, or ventilation systems), they can cause blockages, overheating, and even mechanical failures.

This leads to an increase in unexpected maintenance interventions, raising repair and maintenance costs while reducing machine efficiency. Furthermore, the accumulation of dust shortens the lifespan of equipment and disrupts the production process, directly impacting the plant’s productivity.

SITE DIRECTOR

Paper Factory – France

“In our paper mill, the type of dust we deal with is unlike anything you’d find in other industries. It’s incredibly fine, dense, and compact, making it much harder to remove. This dust isn’t just an aesthetic issue – it settles on equipment, in hard-to-reach places, and even on hot surfaces. The complexity of our operations made it difficult to find an effective cleaning solution that wouldn’t disrupt production.”

Revolutionize

Industrial Cleaning with Zeeef

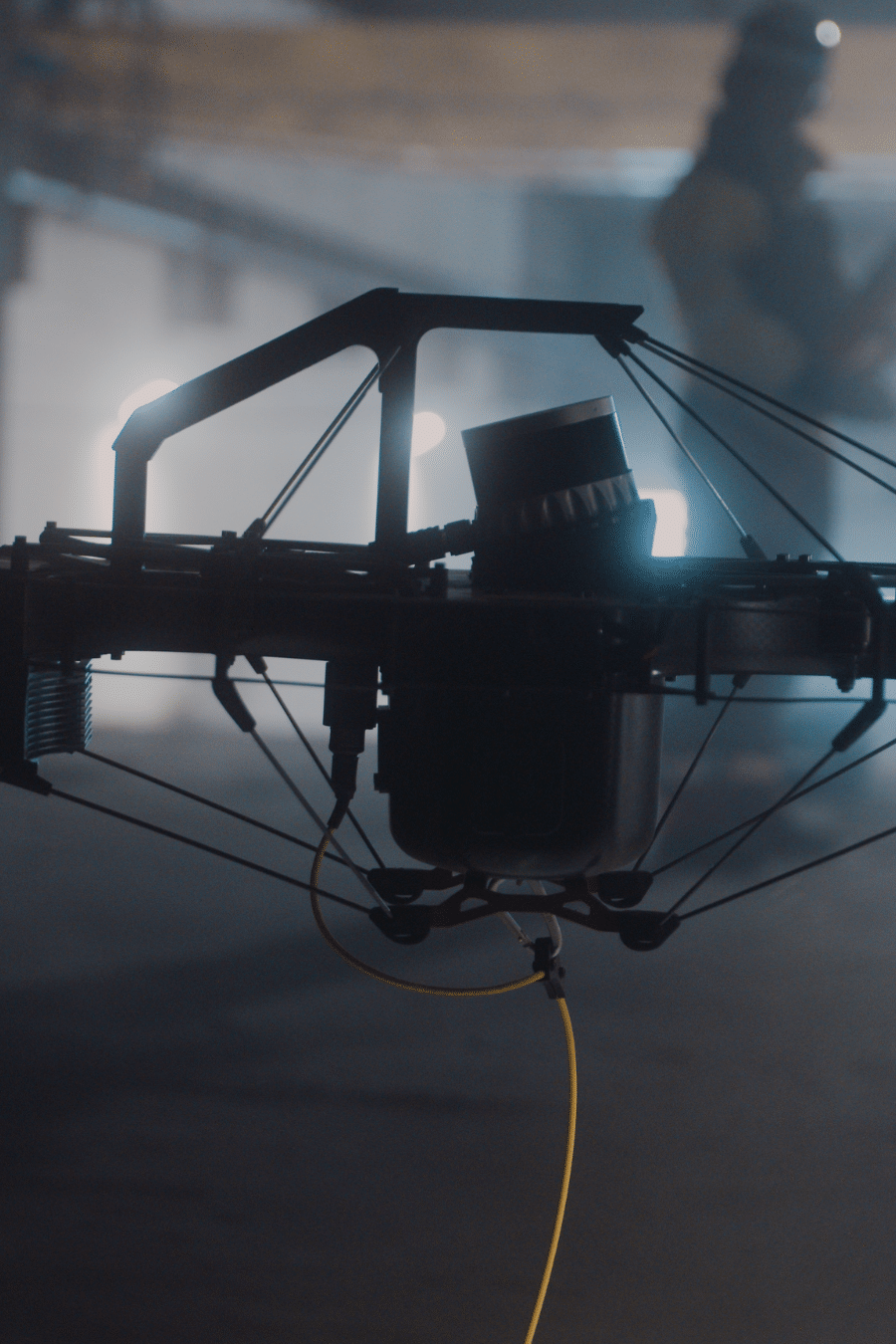

To address these challenges, regular and thorough cleaning of the facilities is crucial to maintain a healthy work environment, optimize equipment performance, and ensure production meets the highest quality standards. Zeeef offers a complete and secure industrial cleaning solution with Scout DI 137 drone & ZF1 Blower Payload.

1. Reliable and Secure Services

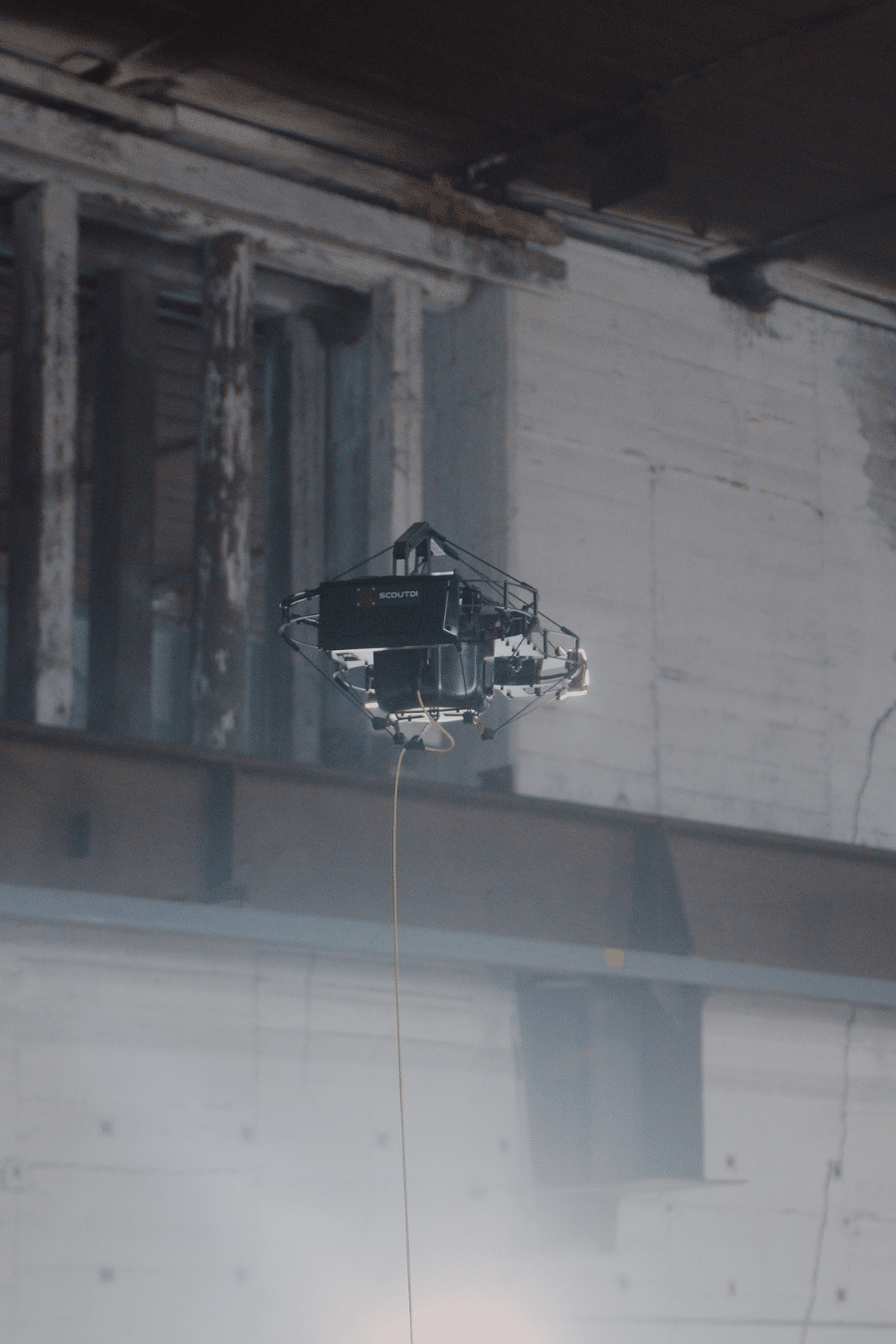

Scout DI 137 drone & ZF1 Blower Payload is transforming industrial cleaning operations by providing a fast, efficient, and safe solution. By eliminating the need for scaffolding or lifts, this innovative tool removes logistical challenges and significantly reduces risks associated with working at height, such as falls, falling objects, or handling accidents.

With its agility and precision, the Scout DI 137 drone & ZF1 Blower Payload can easily reach even the most difficult areas, including high structures, ventilation ducts, and metal beams. Its ability to operate in confined or cluttered spaces ensures a thorough and precise cleaning, all while minimizing risks.

2. Fast & On-Schedule Services

Scout DI 137 drone & ZF1 Blower Payload streamlines cleaning operations by reducing the need for manual interventions, which are often time-consuming and costly. With its speed and efficiency, our industrial dusting drone minimizes production downtime by performing cleaning tasks without the need to dismantle equipment or undergo lengthy logistical setups.

By limiting the use of scaffolding, lifts, and other heavy equipment, this technology reduces costs associated with rentals, labor, and maintenance. Additionally, by enabling more frequent and effective cleaning, it helps extend the lifespan of machines and prevents unexpected breakdowns, thereby lowering corrective maintenance expenses.

This optimized approach enhances productivity, reduces operational costs, and ensures a quick return on investment, making the Scout DI 137 drone and ZF1 blower payload an innovative and cost-effective solution for industrial operations.

3. Efficient Services with

Detailed Performance Reports

The Scout DI 137 drone and the ZF1 blower payload are designed to provide optimal dust removal and residue elimination through advanced, patented blower technology developed in 2017. This blower system, created by Zeeef, efficiently removes all types of textile dust, even the finest and most stubborn particles.

Using the Scout DI 137 drone & ZF1 Blower Payload ensures uniform coverage, removing dust evenly across large surfaces, including high, confined, or hard-to-reach areas. Its ability to move with precision and speed guarantees services of unmatched efficiency.

All services are documented in precise reports, providing clear insights into the effectiveness of each cleaning operation. This ensures transparency, allows performance tracking, and supports data-driven decisions for continuous improvement.

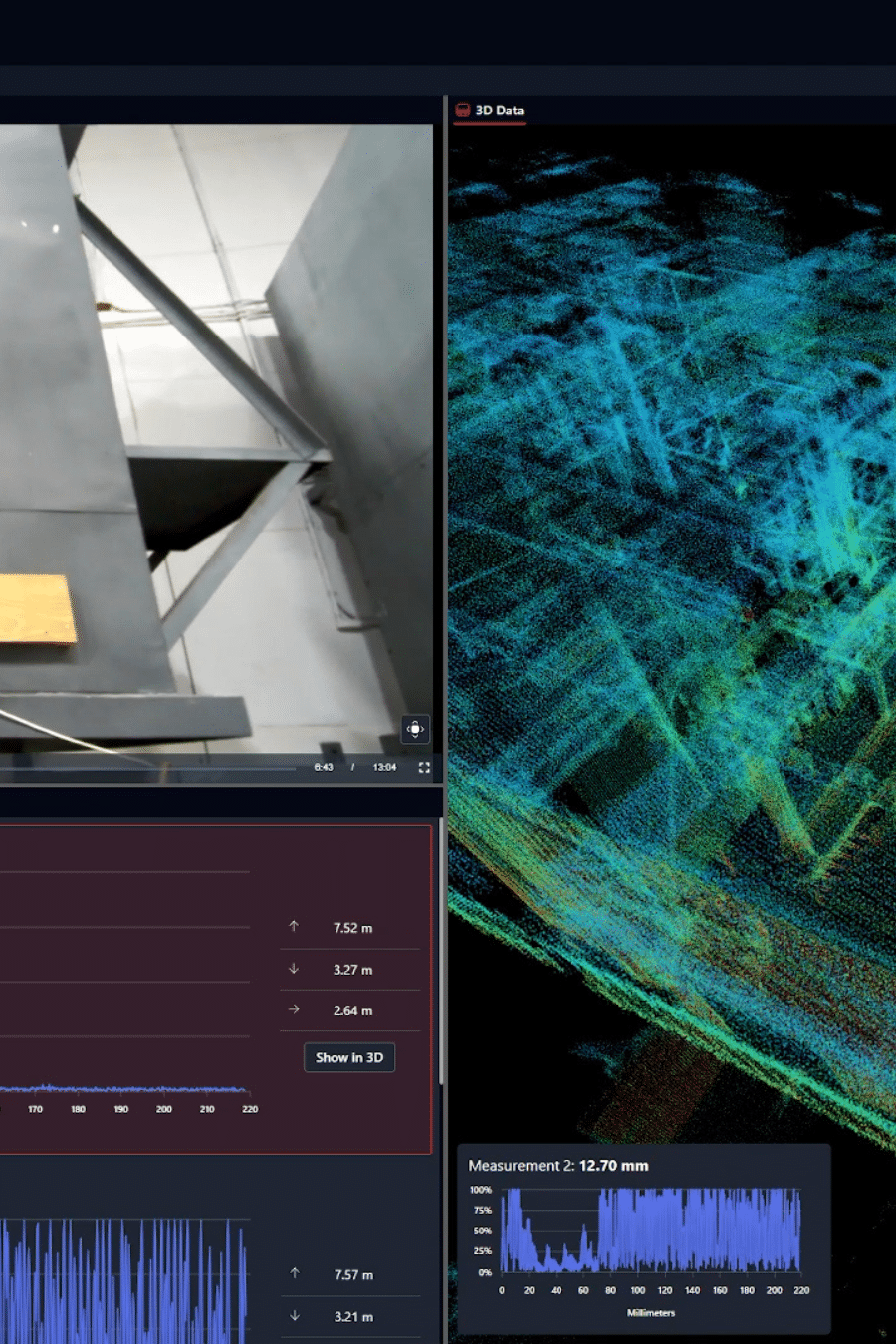

4.Online Platform for Real-Time Service Monitoring and Data Analysis

The Scout Portal online platform, designed for the Scout DI 137 drone, is an advanced solution that enables the analysis, storage, and backup of data from dust removal operations. This platform provides centralized access to the information collected by the Scout DI 137 drone, making it easier to manage data in real time and securely store it for future use.

The portal integrates SLAM (Simultaneous Localization and Mapping) technology, allowing the drone to create detailed 3D models of the serviced site. It generates a 3D point cloud that offers an accurate representation of the cleaned areas, while also highlighting other key points of interest such as structural defects or potential industry-specific risks.

The platform also streamlines the creation of detailed reports, ensuring continuous tracking of the services performed and their effectiveness.